WHAT IS AN LED?

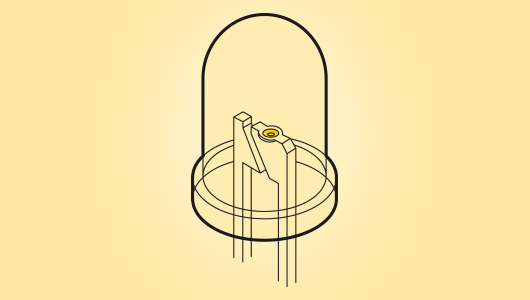

An LED is a light-emitting semiconductor component part that gives off visible light, infrared radiation or ultraviolet radiation as soon as current flows through the diode. Here, the semi-conductor material used is critical for determining the wavelength. An LED consists mainly of an anode, cathode, semiconductor crystal, bond wire and housing. For most LEDs, the cathode also acts as the reflector. The bond wire connects the crystal to the diode. The solder joint forms one of the two electrical connections for the crystal. At the same time, it absorbs the dissipated heat that develops because the semiconductor crystal can convert only a portion of the electrical power into light.

LEDs are operated at a temperature-dependent so-called "operating point", which must be precisely specified or set.

Direct connection of an LED to a voltage source without a series resistor is not possible. Today, LEDs are used in many areas: whether in a smartphone display, LED television, domestic lighting or even modern OP equipment: the small light-emitting diodes are now a fixed part of everyday life.

This also particularly applies to the area of vehicle lighting: in addition to use in main headlamps, high beams and auxiliary lamps, daytime running lights and (combination) rear lights, LEDs are also used for side marker lights and signal lights, for example. As such, a broad range of requirements can also be met for agricultural vehicles: From high-performance LED work lights for close and far-range work via LED beacons with optimal warning effect, through to high-visibility LED side marker lights.

In many cases, agricultural vehicles with conventional lighting can also be easily and professionally retrofitted with LED technology.

Since the very start, HELLA has been one of the pioneers and innovation leaders when it comes to the development and production of LED vehicle lighting. You will encounter thousands of our LED products every day on the roads, whether in daytime running lights and the main headlamps of passenger cars, beacons of emergency vehicles or work lights of agricultural vehicles.

HOW LONG DO LEDS IN HEADLAMPS ACTUALLY LAST?

The question cannot be answered with 100% clarity as the service life of a light source is affected by too many influencing factors. One thing can be said, however: LEDs have a very long service life that is often even longer than the life of the vehicle. This is one of the most significant advantages of LEDs compared to conventional light sources such as halogen lamps. While these light sources can fail over the vehicle"s service life and must then be repurchased and replaced, for example by high-quality HELLA light sources, LEDs are virtually maintenance-free. Together with the low energy consumption and the high energy efficiency, this results in considerable cost advantages for the LEDs over the medium term due to their long service life.

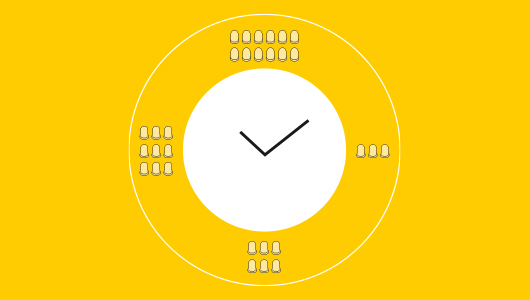

But how long do LEDs really last? Unfortunately there is no simple answer to this question, as already indicated, because a very large number of influencing factors play a role, for example the quality of the utilized LEDs, the frequency with which they are switched on and off, the thermal management system used and many other factors. As a guideline, it can be said that an LED can certainly attain a service life of 30,000 hours and more - whereas conventional halogen bulbs usually fail after just 2,000 - 4,000 hours.

Naturally, even the best LEDs cannot avoid the effects of adverse environmental influences. As a result, even LEDs in headlamps can fail in extremely unfavorable circumstances. These cannot be replaced individually at present. Unfortunately, such scenarios require the complete headlamp to be replaced. But at least with HELLA headlamps, this happens extremely rarely.

ARE LEDS PARTICULARLY ENERGY-EFFICIENT?

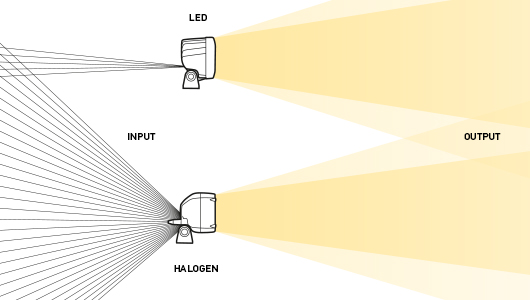

This question can be answered relatively easily: Yes! LEDs are actually very efficient! In addition to the aforementioned long service life, high energy efficiency is one of the main advantages of LED technology. LEDs are like the "top athletes" of the light source world. Though they consume little energy, they achieve a high maximum output and are among the top performers.

Low power consumption saves energy and reduces costs. Even though LEDs are currently somewhat more expensive in terms of acquisition: in the mid-term, it is worth buying them for the lower operating costs alone ─ including for agricultural vehicles. Furthermore, the low power consumption of LEDs has another side effect that should not be underestimated: they are particularly sparing on the energy resources of your agricultural vehicle. This extends the service life of the battery while also helping out the environment by reducing CO2 emissions.

Energy-efficient vehicle lighting is already an important topic and will continue to increase in importance. It is anticipated that the number of electric vehicles will increase considerably in the coming years. This means that careful use of the vehicle"s own energy resources will once again gain particular significance. As a result, the use of highly efficient LED technology is almost inevitable in this field in particular.

DO LEDS GET HOT DURING OPERATION?

It all happens so quickly: When touching or changing a bulb or halogen light source in a tractor headlamp that was just recently used, you burn your fingers. The reason for this is simple: The impressive heat development that is also indicative of poor energy efficiency.

Does this apply to LEDs? The answer is: No. At least not in this form. Although LEDs also generate a certain amount of heat, this heat is considerably lower than that of conventional light sources. Unlike the aforementioned technology, LEDs convert a large portion of the supplied energy into light and not into dissipated heat. LEDs are therefore very energy efficient. One example: A 60-watt bulb has an illuminating power of approx. 600 lumen. In comparison, a current LED bulb that produces 600 lumen only uses approx. 8 watts.

LED headlamps generate very little UV and infrared light. This means, that unlike standard halogen headlamps, they do not heat up where the light is emitted. However, a LED headlamp can still generate heat in the housing. In this case, it is generated by the electronics used for the relevant headlamp, without which optimum light results could not be achieved.

To dissipate the heat generated by the electronics in a reliable and targeted fashion, excellent thermal management is very important. After all, optimal thermal management not only ensures the correct functioning of the headlamp, but also significantly extends the service life.

Need an example? The Ultra Beam Gen. II. work light from HELLA not only integrates LEDs, but also the electronics components in the circuit board fitted in the housing. The heat generated by the electronics, which in extreme cases can be up to 120 °C, is dissipated rearward. By bonding the circuit board to the aluminum housing and using a special heat conducting film, heat can be dissipated in a controlled fashion.

HELLA LED headlamps are therefore not the ideal tool for frying eggs as there simply is not enough heat generated. The headlamps are, however, exceptionally well suited for their target application: Facilitating effective and efficient work during the dark!

WHAT LIGHT COLOR IS EMITTED BY LED HEADLAMPS?

Just like standard lighting technologies, LEDs can generate different light colors. However, in this case, the light color does not refer to a colored light such as red, green or blue LEDs, but the appearance of the light that is generated by white LEDs.

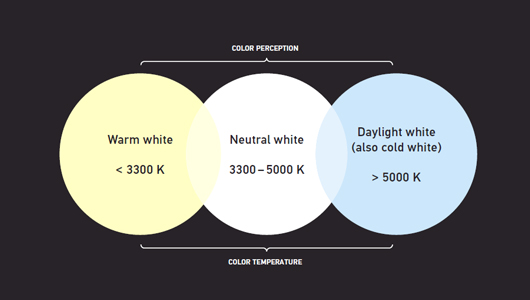

The light color is also referred to as the color temperature and is generally specified in Kelvin. In principle, there are three different color perception areas: warm white (less than 3300 Kelvin color temperature), neutral white (3300 - 5000 Kelvin color temperature) and daylight white (more than 5000 Kelvin color temperature).

LEDs cover the entire spectrum from warm white to daylight white. When it comes to agricultural vehicle lighting, the light color that is similar to daylight is particularly important as it has been proven that this light color illuminates the working area considerably better. High-output work lights in daylight white can therefore make it much easier to perform work in the field, therefore leading to more effective and efficient results. Daylight white also greatly helps counteract driver fatigue that is prone to occurring while working in the dark.

When the LEDs used for HELLA high-power LED headlamps are selected, they are already assessed based on the strictest quality standards regarding the light color and brightness. Both parameters must be within a strictly specified tolerance range. This is the only way that a consistently high and uniform light quality with regard to brightness, light color and other characteristics can be ensured.

An individual"s perception of a color is also subjective, regardless of the actual measurable Kelvin values. Color is thus a sensory impression and without any technical aids, humans are not able to determine the spectral composition of the light.

The world can therefore appear to be much more varied in color than it does for others solely due to the individual"s personal perception!

FOR WHOM ARE LEDS WORTHWHILE?

Direct question - direct answer: LEDs are basically suitable for everyone. In the agricultural sector in particular, LED technology offers users many benefits, including improved illumination and durability, lower maintenance and high energy efficiency.

LED work lights illuminate areas very uniformly and evenly. In conjunction with the daylight white light color, this is particularly advantageous when carrying out field work (both close and far range) in the dark. The working area - here, the field - can be much more easily recognized. LEDs therefore facilitate more efficient work.

Their small design also allows LEDs to be fitted in compact, robust headlamp housings that can withstand greater shock loads as they frequently occur in an agricultural environment. Adding to this is the fact that LEDs will often last as long as the life of the vehicle and are mostly maintenance-free. Faulty lighting and inconvenient bulb replacements as well as purchasing replacement bulbs are thus a thing of the past. Other cost savings can be made thanks to the high-level of energy-efficiency, as the lower power consumption of LED headlamps also reduces fuel consumption. And the lower CO2 output also means that the environment profits!

In many cases, only a few steps are required to convert from halogen technology to the new LED technology. This, in turn, allows you to quickly profit from the many benefits of LED technology without having to buy a new tractor. A conversion example can be found in our demonstrative video.

There are therefore many reasons to fully switch to LED lighting in the agricultural sector!